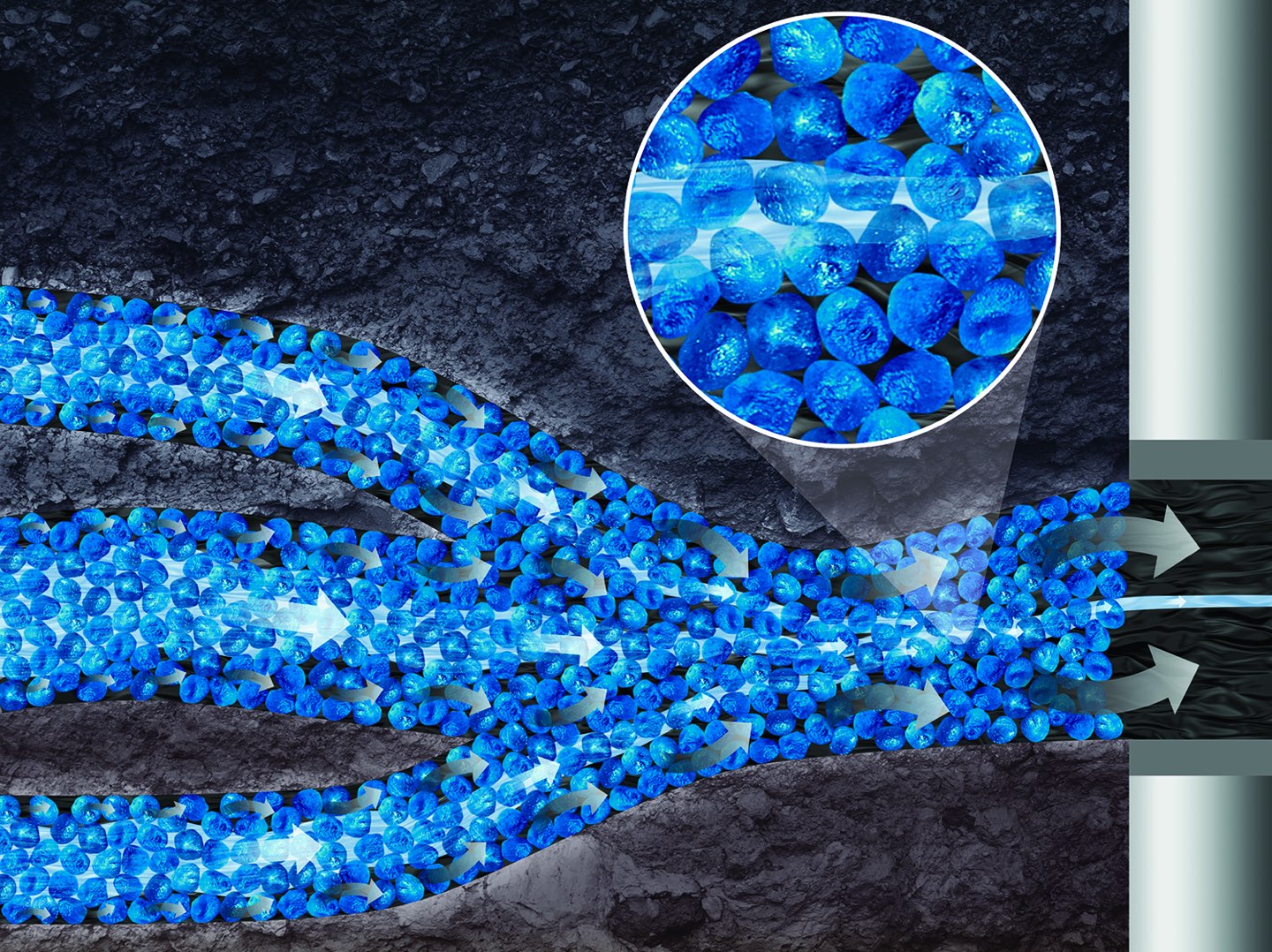

Wind energy blade manufacturers go through a LOT of resin. Large volumes of epoxy resins

and hardeners typically require numerous containers, substantial handling, and significant

residual waste. Hexion Hexi-Bag™ aims to help blade manufacturers address these challenges

through the use of a large-volume packaging system.

Thanks to a 900-1,000 liter capacity in a single Hexi-bag (that’s five times the volume of a

standard barrel), Hexi-bag can result in residual resin of less than 1%, versus 5-10% in

traditional packaging. Larger Hexi-bag packaging can also reduce handling, damaged drums,

and storage requirements. This total logistics reduction can result in a savings of up to 80%.